Physical Model Studies

Project Showcase

Pinnapuram Pumped Storage, 1680 MW, Andhra Pradesh

The Pinnapuram Integrated Renewable Energy Storage Project (IRESP) (1680 MW) is located Andhra Pradesh. The studies were carried out on a geometrically similar Froudian model on a scale of 1: 40 for assessing the flow conditions in the Upper Intake structure during the generation mode as well as pumping mode of operation. The part of upper reservoir, approach channel having length of 973 m and width of 190 m, inlet pool, intake structure including piers, anti-vortex beams, gate shaft and part of penstock were reproduced. According to the studies, the smart geometry-based flow distribution structure was operating as intended. Some modifications to the geometry of intermediate piers of intake structure were suggested.

Vijayanagar Pumped Storage Project, 130 MW, Karnataka

The Vijayanagar Pumped Storage Hydro Project (130MW) is located in Bellary district of Karnataka state of India. The physical hydraulic model studies were conducted on a geometrically similar 1: 25 scale Froudian model for upper intake structure. The part of upper reservoir, approach channel/inlet pool, intake structure including piers, anti-vortex beams, gate shaft and part of penstock were reproduced. Flow distribution, flow conditions, velocities and pressure parameters were evaluated for the intake structure, approach channel and inlet pool. Sedimentation studies were also carried out. Model studies provided insight into the hydraulic behavior of the system and suggestions were provided regarding the overall operation of the system during generation mode of operation.

Phata Dam Spillway, 76 MW, Uttarakhand, INDIA

Mandakini River flowing through great Himalayas, had a devastating flood in July 2013. Phata Hydropower project is located just at the foothills of Kedarnath on Mandakini River. Phata dam was the first major structure, which got heavily damaged due to these unprecedented floods. Phata run-off-the-river spillway dam, a 76 MW Hydropower project, is now all set for the re-construction, after the physical model studies confirmed its suitability. Model is built on a physical scale of 1:35. The river is very steep at the location of dam having a slope in order of 1:8, vertical to horizontal. The hydraulic designs, discharging capacity, dam layout, as well as power intake operations were optimized in the model.

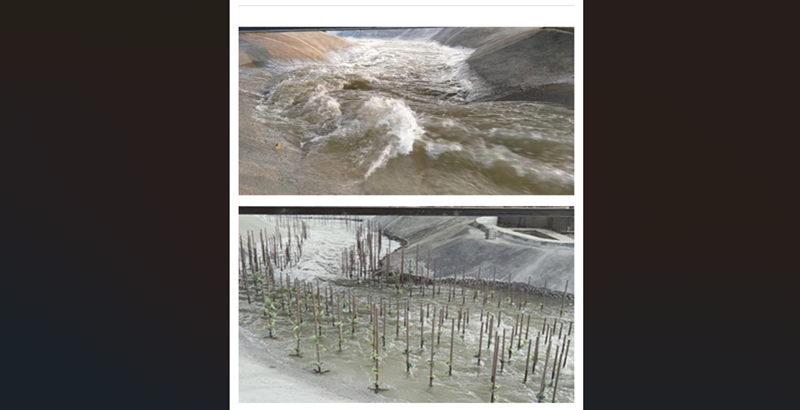

Annaram (Saraswathi) Barrage, Kaleshwaram Lift Irrigation Scheme, Telangana

Annaram Barrage is a part of Kaleshwaram project which is a prestigious & world’s biggest multi-stage Lift Irrigation Scheme situated in Telangana state of India. During the initial operations of the barrage, few damages were observed to the downstream protection works, post 2019 Godavari floods. IHL was involved in investigations to identify the causes and to suggest remedial measures. Site visit along with the review of hydraulic designs suggested the inadequate tail-water levels affecting the performance of stilling basin. The sectional 2D model on a scale of 1:45 was constructed at IHL to assess potential alternatives for improving the energy dissipation. Extensive studies were carried out and introduction of extended/secondary stilling basin having lowered apron and raised end sill was suggested. The geometry and levels of extended stilling basin were optimised in the model. Further the gate operation schedule was also suggested for the barrage.

Pakal Dul Hydro Electric Project, 1000 MW, Jammu & Kashmir (J&K), INDIA

The Pakal Dul HEP envisages construction of a Concrete Faced Rockfill Dam of 167 m having the installed capacity of power 1000 MW, on the Marusudar River in Kishtwar District of Jammu and Kashmir, India. The hydraulic model studies were conducted on a geometrically similar 1: 40 scale model for Tunnel Spillway and Power Intake Bulkhead and Service Gates. The model studies were conducted to assess the overall hydraulic performance of water conductor system for Tunnel Spillway as well as Power Intake and to estimate hydrodynamic forces and flow conditions in the gate wells including upstream and downstream transitions.

Allain Duhangan Hydropower Project, Himachal Pradesh, INDIA

It is a 192 MW run-off-the-river Hydro Power Plant having a net head of 860 m located in Manali. The present arrangement of Heat Exchangers at downstream of turbines is experiencing heavy sediment deposition which is affecting its performance and efficiency. A physical hydraulic Froudian model on a scale of 1:10 was constructed to assess the cause of sedimentation and analyse the effect of suggested remedial measures qualitatively. Calibration of the model with respect to the prototype measurements was carried out. Sediments were simulated in the model.

Haliyal Lift Irrigation Scheme, Karnataka, INDIA

A Lift irrigation Scheme is proposed at Dandeli, Uttara Kannada district, in Karnataka known as ‘Haliyal Lift Irrigation Scheme (Haliyal LIS) under Karnataka Neeravari Nigam Ltd. The objective of the hydraulic model study was to ensure swirl free flow conditions at suction bell mouth of pump stage. Based on calculations and scale analysis, a 1:6 comprehensive, geometrically similar, three-dimensional model based on Froudian similitude was constructed for pump sump structure and intake structure. Model studies were conducted for different combinations of pump operation conditions at two water levels; MDDL and MDDL +3 m.

Nagalwadi Lift Irrigation Intake, Madhya Pradesh, INDIA

Lift irrigation scheme is under construction on the Narmada River at Nagalwadi. It is planned to irrigate 45,000 ha of agricultural land in Madhya Pradesh. The entire scheme envisages seven stage pumping. The main pump intake consists of 5 V.T. Pumps, each having a discharge of 3.75 cumec. The geometrically similar Froudian model was constructed on a model scale of 1:12.5 to observe the flow conditions at the intake. The operational matrix was studied for various pump operating combinations and hydraulic designs were verified.

Chorokhi River, Batumi, GEORGIA

Perhaps one of the biggest model ever constructed in laboratory spread over 70 m x 30 m. River length of 2.5 km was reproduced along with some part of seabed. Part of the coast near the mouth of Chorokhi river is eroding for last few decades. The geometrically similar rigid bed physical hydraulic model on the scale of 1:50 confirming to Froudian similitude was constructed to assess the hydraulic performance and sediment movement near Chorokhi river mouth. Mathematical model in Hec-RAS was prepared for the reach of 3 km from river mouth. The mathematical model was used to arrive and compare the water surface profiles and Manning’s n values in various sections of river reach.

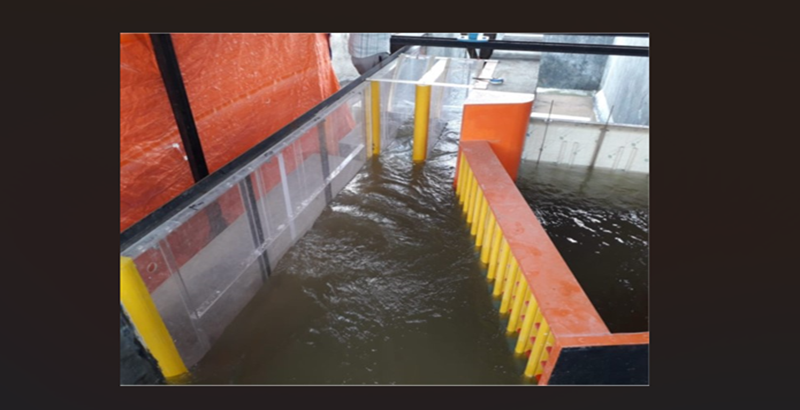

Nam-E-Moun, LAOS - Calibration of river models

Nam-E-Moun Hydro power project having an installed capacity of 128 MW, is being developed in Laos PDR, which envisages two spillways on two rivers, Nam-E-Moun and its tributary Huvey-Het. Both spillways and power intake structures were modelled. Rivers are reproduced for some upstream and downstream portion, on a Freudian model scale ratio of 1:40. Both the rivers have a peculiarity that they are having very steep banks with high vegetation cover consisting of tall trees. Estimation of the water levels during high floods as well as prediction of the impact of spillway structure was a challenging task. Model trees and pebbles, grit, were used to reproduce the high friction along the banks. Its effect on the river course was evaluated. The water levels in both the rivers were calibrated. After due calibration of the river models, spillway and intake structures were installed in the river.

Nam-E-Moun, LAOS - Spillway Models

Various model studies were carried out to evaluate the discharging capacity of the spillways, upstream flow conditions, energy dissipation on the downstream and adequacy of structures. Further, the detailed experiments were carried out for preparing the gate operation schedule to guide the authorities during the prototype operations. A very good insight was gained with respect to the overall flow conditions from model studies and some modifications were suggested with respect to downstream apron and gate operations.

Nam-E-Moun, LAOS - Desander Models

The desilting basins (Desanders) of Diversion dam and Main dam were modelled on a Froudian scale of 1:16. Detailed model studies were carried out for evaluating the performance of desilting basins in trapping the suspended load. The coconut shell powder having low specific gravity, was used to simulate the suspended particles. Coconut shell powder proved to be good alternative in view of the shortage of walnut shell powder. Both desanders were found to be more than 90% efficient in trapping the suspended particle size of more than 0.2 mm. The flushing studies were carried out, to formulate the flushing methodology, and to optimize the quantity of water and time required for flushing.

Super Trishuli 2D Model for Spillway, NEPAL

A 100 MW Hydro Power Project is planned on Trishuli River in central Nepal. The project is located along the Kathmandu Pokhara ‘Prithvi’ Highway, and it is a run-of-the-river type project with Dam Toe Powerhouse arrangement having a capacity of 100 MW of power generation. The project is planning to install very high radial gates. A two-dimensional physical model is built to evaluate the performance of energy dissipation arrangement provided in the form of stilling basin at downstream of spillway. The model is called two dimensional, as only one or two spans are reproduced in the model, out of total five spans of spillway. Model studies highlighted the need to lower the height of radial gates and addition of one or two spans of spillways, to improve the energy dissipation arrangement. The improvement in stilling basin is also suggested.

Dagacchu Head Race Tunnel, BHUTAN

Hydraulic model for Head race tunnel of Dagacchu Hydro-Power Project, Bhutan, was the first physical model built by IHL. The head race channel was transitioning into the pressurized tunnel. Due to the difference in the elevations during excavation stage, the transition was not as smooth as originally planned. Numerical analysis showed that vortex will form at upstream of transition. To verify this, the transparent Perspex model was built, to observe the flow pattern inside the transition. The air entraining vortex was observed at high flows. To eliminate this, an anti-vortex device in form of a beam was suggested. The location and sizing of beam was optimized in the model and implemented successfully on the site as well.

Project Map

Get In Touch

Kolhapur Office: 109, Raoji Complex, 1st Lane, Shahupuri Kolhapur- 416001 Maharashtra, India.

Pune Office: Office No. 215, 2nd Floor, Kohinoor Majestic, Behind Kundan Hyundai, Thermax Chowk, M.I.D.C. Chinchwad, Pune. 411019

Hydraulic Laboratory: Chandkhed Village, Tal- Maval, Dist. Pune, Maharashtra, India.

Telephone: +91-231-2655151

Mobile: +91-9404265151, +91-8379809080

Email: contactus@infraplan.in